Import Dependence Hurts Mazda: Crossover Strategy Impacts Manufacturing

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit Best Website now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Import Dependence Hurts Mazda: Crossover Strategy Impacts Manufacturing

Mazda's ambitious crossover strategy, while boosting sales, is simultaneously exposing vulnerabilities in its manufacturing and supply chain, leading to increased import dependence and raising concerns about future growth. The automaker's reliance on imported parts is impacting production efficiency and profitability, highlighting a crucial challenge for the Japanese car manufacturer in an increasingly complex global market.

The Crossover Boom and its Unexpected Consequence

Mazda's recent success is largely attributed to its popular crossover SUVs, like the CX-5 and CX-30. These models have driven significant sales growth, solidifying Mazda's position in the competitive automotive landscape. However, this success comes at a cost. The increased demand for these vehicles has exposed a critical weakness: a heavy reliance on imported components.

This dependence is not merely a logistical hurdle; it's impacting several key areas of Mazda's operations. Fluctuations in currency exchange rates, global supply chain disruptions (like those experienced during the pandemic), and escalating transportation costs are all directly impacting Mazda's bottom line. Furthermore, this reliance on external suppliers makes Mazda vulnerable to geopolitical instability and unexpected events.

Manufacturing Challenges and Regional Disparities

Mazda's manufacturing footprint is concentrated in certain regions, leading to regional disparities in production capabilities. While some plants excel in certain aspects of vehicle production, the reliance on imported parts necessitates a complex and potentially inefficient global supply chain. This intricate web of suppliers increases the risk of delays and disruptions, hindering Mazda's ability to meet the growing demand for its crossover vehicles.

A Strategic Shift Necessary?

Experts suggest that Mazda needs to re-evaluate its manufacturing strategy to mitigate the risks associated with its high level of import dependence. Options include:

- Reshoring or Nearshoring: Bringing production of key components back to Japan or relocating them to geographically closer regions. This would reduce transportation costs and increase control over the supply chain.

- Strengthening Local Partnerships: Developing stronger relationships with local suppliers to ensure a more reliable and stable supply of components.

- Investing in Automation: Implementing advanced automation technologies could reduce reliance on manual labor and potentially offset some of the cost pressures associated with imported parts.

- Diversification of Suppliers: Reducing reliance on a small number of suppliers by cultivating relationships with multiple vendors across different regions.

The Long-Term Outlook for Mazda

Mazda's current predicament highlights the challenges faced by automakers in navigating the complexities of global manufacturing. While its crossover strategy has undeniably contributed to its recent success, the significant import dependence needs to be addressed proactively. Failure to do so could potentially hinder future growth and profitability. The company's ability to adapt and implement a more resilient and localized manufacturing approach will be crucial in determining its long-term success in a fiercely competitive market.

Keywords: Mazda, crossover, SUV, manufacturing, import dependence, supply chain, automotive industry, global manufacturing, production, profitability, near shoring, reshoring, automation

Call to Action: What are your thoughts on Mazda's current manufacturing strategy? Share your opinions in the comments below.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Import Dependence Hurts Mazda: Crossover Strategy Impacts Manufacturing. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Md Lottery Results Mega Millions And Pick 3 Winning Numbers For September 2nd 2025

Sep 04, 2025

Md Lottery Results Mega Millions And Pick 3 Winning Numbers For September 2nd 2025

Sep 04, 2025 -

Social Medias Grip Sapient America On Addiction And Parental Guidance

Sep 04, 2025

Social Medias Grip Sapient America On Addiction And Parental Guidance

Sep 04, 2025 -

Update Lady Gaga Song Excluded From Wednesday Soundtrack

Sep 04, 2025

Update Lady Gaga Song Excluded From Wednesday Soundtrack

Sep 04, 2025 -

2023 Nfl Playoffs Which Fringe Teams Are Most Likely To Make The Postseason

Sep 04, 2025

2023 Nfl Playoffs Which Fringe Teams Are Most Likely To Make The Postseason

Sep 04, 2025 -

Espn Analyst Weighs In Examining Deion Sanders Clock Management Strategy At Colorado

Sep 04, 2025

Espn Analyst Weighs In Examining Deion Sanders Clock Management Strategy At Colorado

Sep 04, 2025

Latest Posts

-

Jannik Sinner Cruises Past Lorenzo Musetti At Us Open

Sep 05, 2025

Jannik Sinner Cruises Past Lorenzo Musetti At Us Open

Sep 05, 2025 -

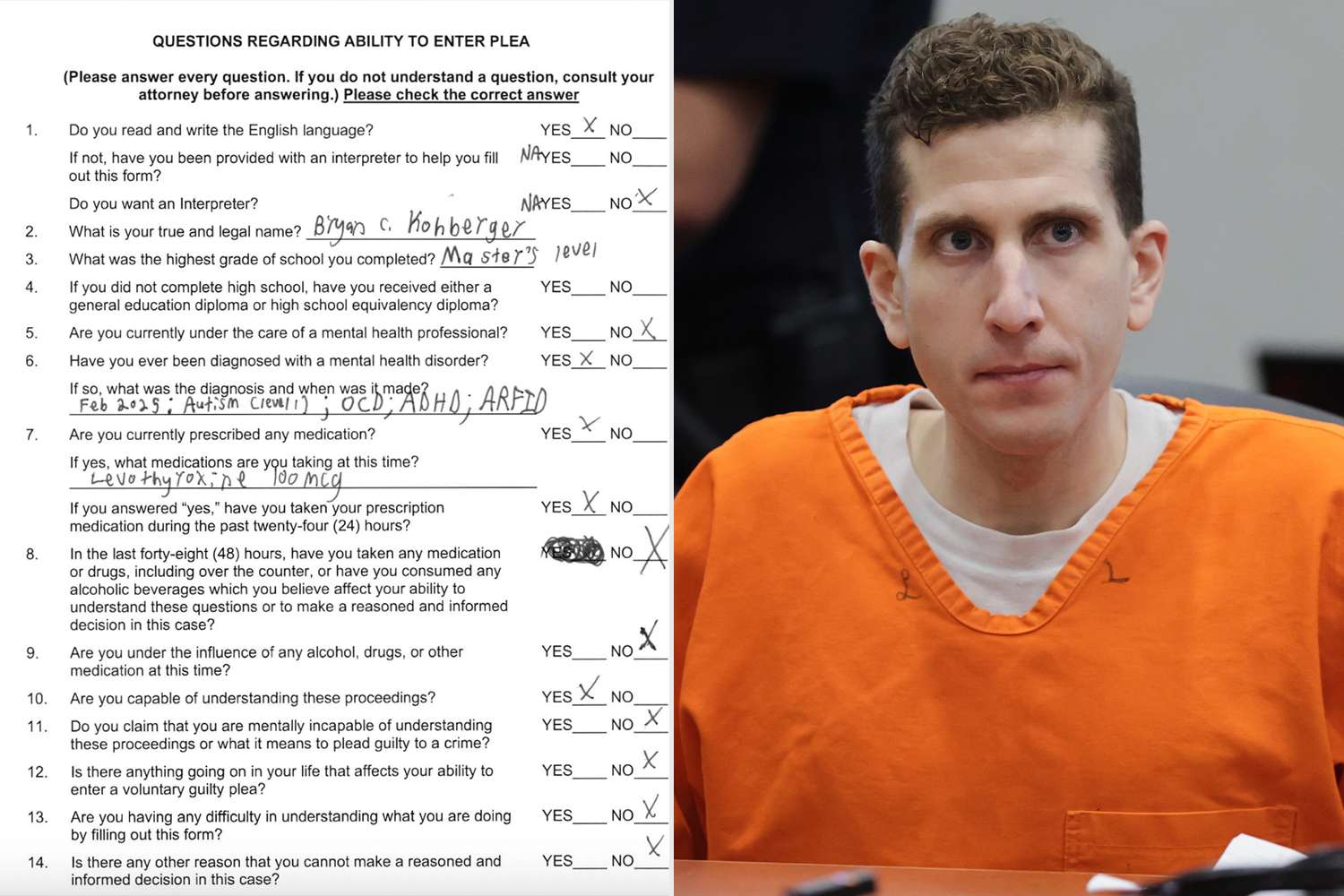

Idaho Murders Bryan Kohberger Reveals Mental Health Disorders In Guilty Plea

Sep 05, 2025

Idaho Murders Bryan Kohberger Reveals Mental Health Disorders In Guilty Plea

Sep 05, 2025 -

Super Bowl Lx Prediction Chiefs Buccaneers Rematch On The Cards

Sep 05, 2025

Super Bowl Lx Prediction Chiefs Buccaneers Rematch On The Cards

Sep 05, 2025 -

One Number Away Family Wins 150 000 In Powerball Misses 1 Billion Jackpot

Sep 05, 2025

One Number Away Family Wins 150 000 In Powerball Misses 1 Billion Jackpot

Sep 05, 2025 -

2025 Nfl Week 1 Preview 49ers Secure Jennings For Upcoming Season

Sep 05, 2025

2025 Nfl Week 1 Preview 49ers Secure Jennings For Upcoming Season

Sep 05, 2025